CSST

PROJECT NAME

City of Ottawa’s Combined Sewage Storage Tunnel Project

CONTRACTOR

Dragados / Tomlinson - Joint Venture

OWNER

PRODUCTS USED

Custom 3000 mm Ø Precast Concrete Jacking Pipe

Radius Concrete Pipe

Concrete Pipe Bends

Other Various Custom and Standard Products

ENGINEER

Stantec / CH2MHILL

PROJECT DESCRIPTION

Many municipalities across Canada are currently challenged with the impacts of climate change. For municipalities with combined storm and sanitary sewers, extreme rain events can result in the discharge of raw sewage into local rivers and lakes that surround these municipalities. The Combined Sewage Storage Tunnel (CSST) is one of the key projects included in the Ottawa River Action Plan (ORAP) which is the City of Ottawa’s roadmap to protect the Ottawa River for future generations. The CSST project is a $232.3 million investment. The purpose of the CSST will be to greatly reduce the frequency of sewage overflows, during major rain events, from entering the Ottawa River, and will help protect the river’s water quality and reduce beach closure as well as improve the long-term health of the river’s ecosystem. The tunnels that make up the CSST will hold up to 43,000 m3 of sewer overflow during major rainfalls. This is the equivalent capacity of approximately 18 Olympic-sized pools. Once the rainfall has subsided, the sewer overflow water will then be treated and returned safely to the Ottawa River.

Since 2016, M CON has been working with project consultant engineers and structural design engineers to design and manufacture unique precast concrete products for various applications. Some of the products made were:

• A custom-sized 4200 x 1200 mm box culvert

• 3000 mm and 1800 mm diameter jacking pipe

• Radius reinforced pipe

• Pipe bends of various sizes

• Custom roof panels

• Custom slabs

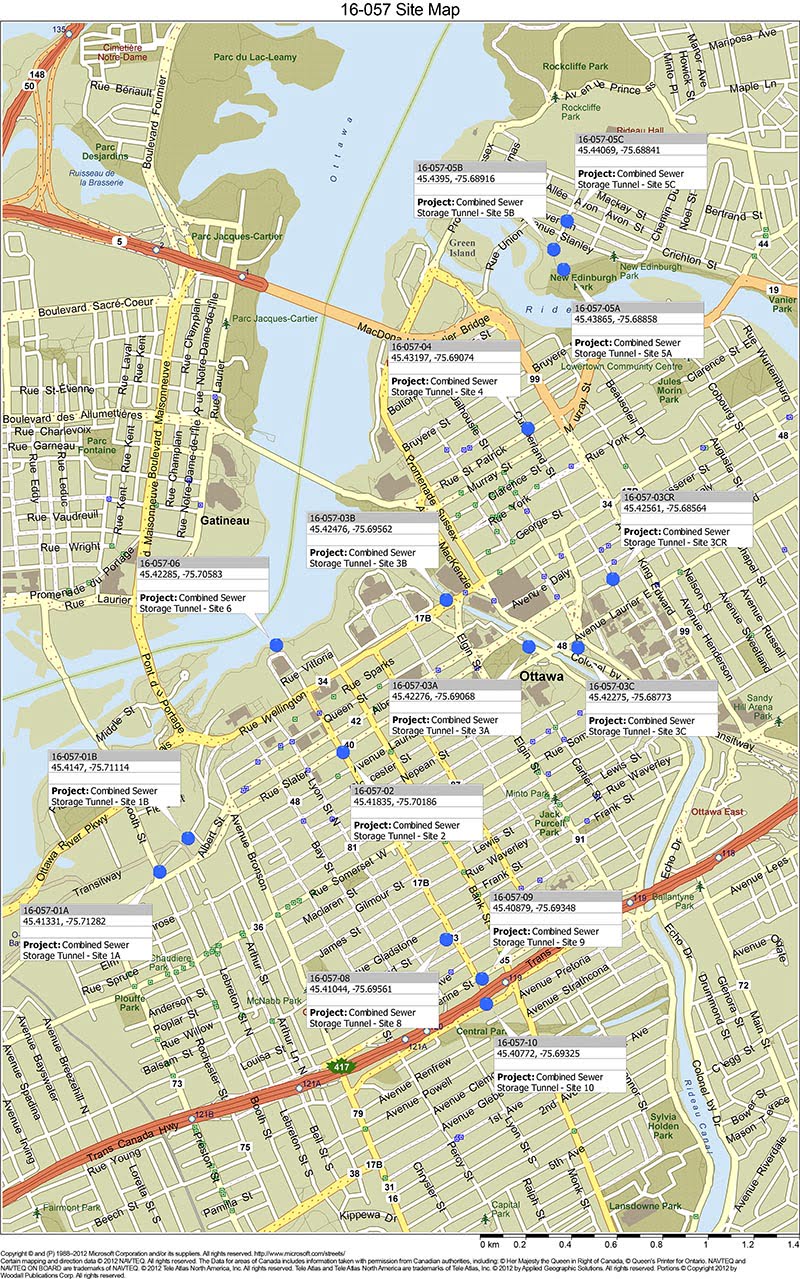

M CON provided products to fifteen different sites for this project scattered throughout downtown Ottawa. Although the products listed are typically used as drainage products in most projects, M CON in conjunction with the consultant proposed alternative uses for these structural elements. Some of the alternate uses for them such as air ventilation structures (made with pipe or maintenance hole components) and access shafts of various sizes for gigantic cast-in-place structures. All the structures required custom grates and hardware, supplied by M CON for the customer’s convenience.

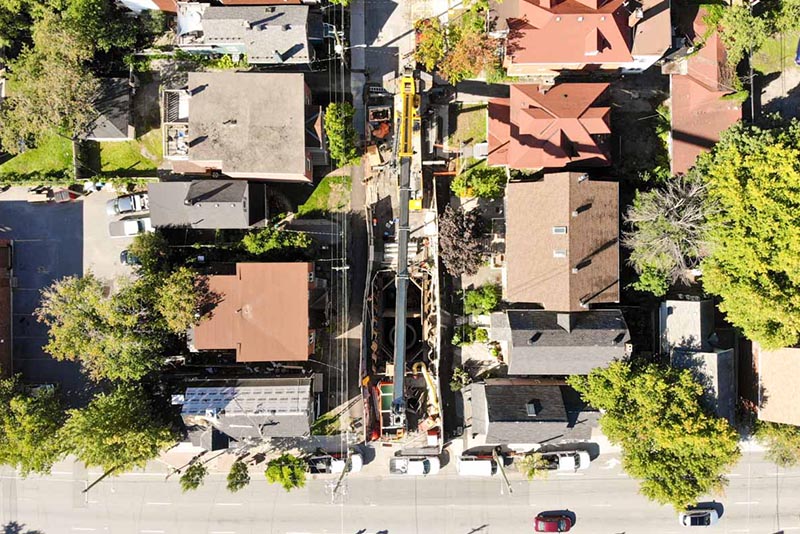

The 3000 mm diameter jacking pipe for Site 8 was designed as per CSA A257.4-19. They included ten 20-ton swift lift anchor points, as opposed to the usual two anchors because the shaft that the product was lowered down in was too narrow to lower the pipe in its final configuration. The 19,000 kg pipe had to be carefully lifted on a narrow street, lowered down the shaft in a vertical position and then carefully rotated to its horizontal position 18 m (or six stories) below the street and jacked into place.

M CON collaborated closely with the contractor and consultants to ensure the ease of installation. The 3000 mm jacking pipe was a quicker and safer alternative to a tunnel lined with panels or shotcrete. The 3000 mm jacking pipe was used at three different locations for a total of fifty-four metres.

Logistics was also an important aspect of this project as M CON provided products to fifteen different sites for this project scattered throughout downtown Ottawa. There were always multiple sites active at any given time. Since this was a joint venture, along with multiple sites there were multiple site supervisors from multiple companies. Clear communication and planning were required to ensure products arrived at the correct site at the correct time, especially with the 3000 mm pipe which can only be shipped one piece at a time due to their weight.